Sodium fatty alcohol polyoxyethylene ether sulfate-AES

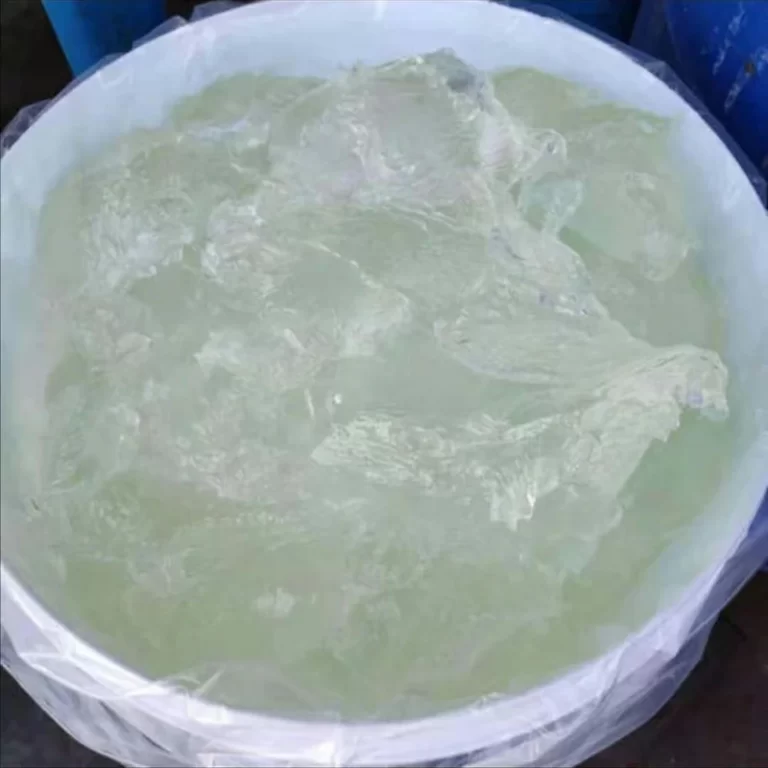

Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate, Sodium Dodecyl Alcohol Polyoxyethylene Ether Sulfate, Sodium Lauryl Alcohol Polyoxyethylene Ether Sulfate, AES Sodium Salt, Sodium Ethoxylated Alkylated Sulfate CAS: 9004-82-4 Chemical Formula: C14H29O5NaS White or light yellow gel-like paste, easily soluble in water. It has excellent decontamination, emulsification and foaming properties. Biodegradable, biodegradation degree is more than 90%.

Product Use

It is one of the main raw materials for liquid detergents, shampoos, foam baths, hand washing agents, etc. It can also be used as lubricants, dyeing aids, cleaning agents, etc. in the textile industry.

Performance and Applications

Easily soluble in water, with excellent decontamination, emulsification, foaming properties and resistance to hard water, mild washing properties will not damage the skin. Please note when using: In the absence of viscosity modifiers, if AES is to be diluted into an aqueous solution containing 30% or 60% of the active substance, it will often result in a viscous gel. To avoid this phenomenon, the correct method is to add the highly active product to a specified amount of water while stirring. Do not add water to the highly active material, as this may lead to the formation of a gel. This product is used in the textile industry as a component of vinylon oiling agent and other synthetic fiber oiling agent. It can also be used as raw material of liquid synthetic detergent, with the advantages of good diffusibility and strong washing effect. It is used in daily-use chemical industry, textile, petroleum, leather, printing and dyeing and other industries. Building materials mortar king

Test Report

| Test items | Standard value | Measured value | Detection Methods |

| Appearance (30°C) | White crystals | White crystals | 60044625 |

| coloration | 10max | 5 | GB/T9282. 1- 2008 |

| Moisture % | 0.15max | 0.02 | GB/T 11275-2007 |

| Acid Value mgKOH/g | 0.2max | 0.02 | GB/T 16451-2017 |

| Saponification Value mgKOH/g | 0.8max | 0.28 | GB/T 16451-2018 |

| lodine Value gI-/100g | 0.8max | 0.15 | GB/T 16451-2019 |

| Hydroxyl Value mgKOH/g | 205~220 | 212 | GB/T 16451-2020 |

| Melting point ℃ | 52~58 | 53.7 | GB/T 16451-2021 |

| Hydrocarbon alkyri % | 1.0max | 0.64 | GC area normalization method |

| (16+18)Main components% | 98.5min | 98.77 | GC area normalization method |

| Total Alcohol% | 99.0min | 99.36 | GC area normalization method |

| ≤C14 sterols | 1.0max | 0.03 | GC area normalization method |

| C16 sterols | 23.0~25.0 | 27.97 | GC area normalization method |

| C18 sterols | 65.0~77.0 | 70.8 | GC area normalization method |

| C20 sterols | 1.0max | 0.27 | GC area normalization method |

Package specification

Specification:170kg