How to test the performance of ink?

The quality of the ink directly affects the correctness and stability of the color of the printed product. The water-based ink used in flexographic printing has the characteristics of low viscosity and low pollution. Ink management is mainly through the detection of ink hue, coloring power and sunlight resistance to achieve the control of ink color quality parameters and eliminate color deviation from the source. Ink testing and related information can be provided by the supplier or tested by the printing company itself.

1. Ink hue, coloring power detection

Hue, coloring power is the basic items of ink testing, they have a great impact on the color of the ink. Hue is the specific characteristics of the ink color, in the optical corresponds to a certain wavelength, frequency of light, such as: red, yellow, blue refers to the hue of the ink.

Coloring power refers to the size of an ink that affects the degree of color change of another ink. When blending spot-color ink, when one of the original ink hue or change, the color of the blended spot ink will change.

For example, when the color phase of the original ink is more yellow than before, the spot color ink deployed will have the effect of increasing the yellow color; if the coloring power of the original red ink is strong, it will have the effect of increasing the red color. When this color deviation exceeds a certain range, it can be detected by visual inspection, which leads to customer complaints.

Therefore, to ensure the correctness of the printing ink hue, the stability of the coloring power, is very important to control the color of printed materials.

2. Detection of color hue

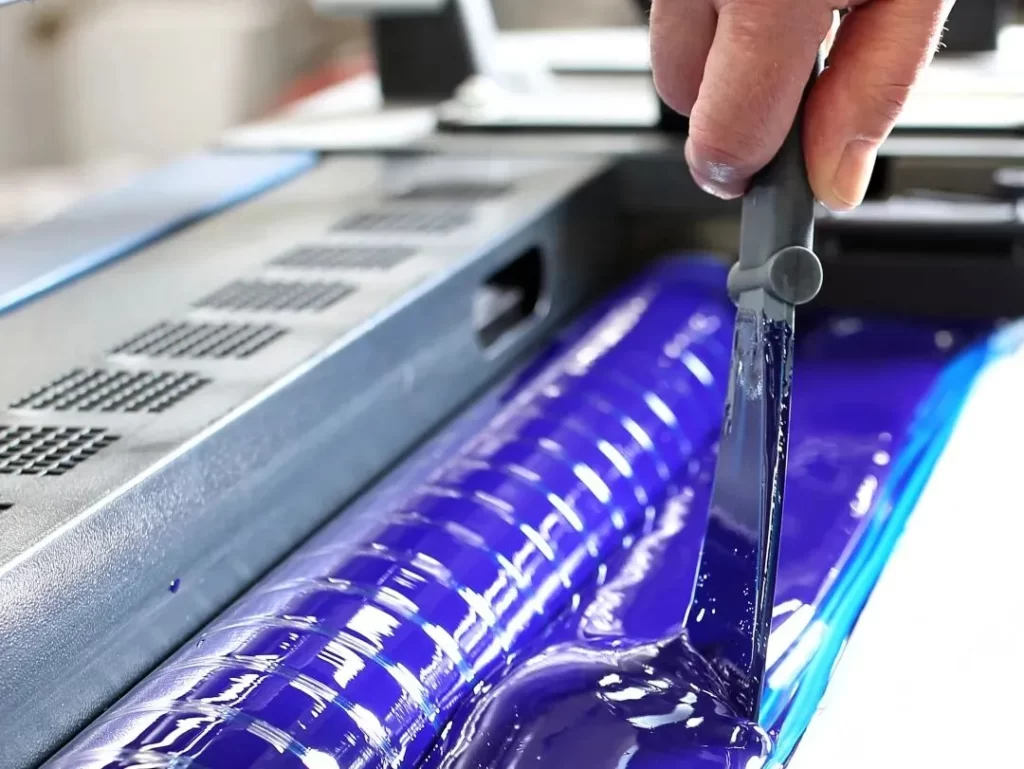

The new ink provided, generally to adjust its viscosity to the machine viscosity, with the printing machine proofing, to the field version of this ink printed color samples, or the ink in a good adjustment of the pressure of the spread of several drops of color wheel, with a certain pressure, speed in the substrate surface dragging, playing a color band as a color sample.

Observe the effect of these samples, if the ink layer is uniform and smooth, good coloring, a certain luster, ink color is thick and solid, the same color as the standard color card provided by the supplier (can be provided by the ink factory production) is basically the same, it means that the color phase of this ink meets the requirements. Finally, you can take a certain amount of this test ink sealed and stored, in order to be used as a reference wet color sample for the next color phase test.

For the once-used ink, the ink viscosity can be adjusted to the appropriate value, with a color wheel to play the color sample, with the last plate to retain the qualified color sample or standard color sample for comparison, you can initially detect whether the color phase is consistent. Another method is to test the ink with the last detection of qualified ink wet color sample, in the spreading color wheel about 25px away from each drop, side-by-side layout.

At this time in the plate paper will leave two adjacent color band, against these two color band can be more accurate to determine whether the color phase is the same.

3. Coloring power detection

Ink coloring power detection is to use white ink as a reference color sample, through the degree of influence of a certain ink on the white ink to determine the strength of its coloring power degree. Coloring power detection is in a small beaker to be tested by adding ink and standard color ink, stirring well before playing the plate, and then compared with the standard coloring power color sample to compare and judge the strength of the ink coloring power. Specific practices are as follows.

Add 10g of ink to be tested and 100g of standard white ink in a small beaker, stir well and then use the spreading color wheel to hit the plate, hit the color sample and the standard ink coloring power color card provided by the supplier, if the ink color is lighter, it means that the ink coloring is weak, if the ink color is darker, it means that the ink coloring power is strong, if the basic agreement means that the coloring power is qualified.

In addition, can be tested by increasing the weight of the ink to be tested or standard white ink to detect the strength of coloring power changes. Light ink can be appropriate to increase the weight of the ink to be tested, such as in a small beaker and then add 2g of ink to be tested, stirring evenly with a color wheel to hit the color sample, if the same as the standard color sample, then according to (10 + 2):100 = 10:x calculation, you can launch x = 100 × 10 ÷ 12 = 83.3 (g), indicating that the coloring power of this color ink is only 83.3% of the standard color ink, which can also be said to be weak 16.7g.

Ink dark can be appropriate to add the weight of white ink, if in a small beaker and then add 10g of standard white ink after playing the color sample with the standard color card, then by 10: (100 + 10) = 10: x launched = 110 (g), that the coloring power of the ink to be tested is 110% of the standard ink, it can also be said that the strong 10g.

All the x’s above represent the weight of white ink when a certain amount of white ink is added to 10g of the ink to be tested to meet the standard coloring power color card, which means that the strength of the coloring power is measured by the amount of white ink.

In addition, there is a wet color sample control comparison method, that is, the ink to be tested for color strength testing wet color sample with the previous determination of qualified ink color strength testing wet color sample in the spread color wheel side by side layout, after playing the color sample for wet color sample control. This test method eliminates the wet color sample with the dry color sample between the existence of color bias and the true results of the assessment of the drawbacks, because they are wet color sample and adjacent, so the comparison of color convenience, high accuracy some.

After doing the coloring power and hue test, remember to keep the wet color sample and dry color sample of the test, especially the wet color sample and dry color sample of the standard ink must be sealed and kept and marked well for the next test. Because the spot color requirements of color stability, so the ink color phase requirements are correct, coloring power requirements to maintain stability, the general standard is: ± 10% within the acceptable, within ± 5% for qualified, not high, nor low.

4. Detection of ink viscosity

Liquid ink viscosity is relatively low, fluidity is relatively good, the detection of viscosity is also very simple, only a viscosity cup and a stopwatch to complete the detection of ink viscosity.

The specific operation method is: stir the ink first, then immerse the viscosity cup into the ink, and then put forward the viscosity cup at an even speed. In the viscosity cup just pulled out of the ink surface, press the stopwatch timing, viewing the outflow of ink; when the ink just have a break in the flow point immediately press the stopwatch. At this time, the time value on the stopwatch that represents the ink viscosity, viscosity, high number of seconds; viscosity, low number of seconds. As the temperature is different, the viscosity of the ink will also change, therefore, the general detection temperature is fixed at 25 ℃.

It is worth mentioning that there is no obvious correlation between the temperature and the color of the ink, but there will be some influence on the performance of the ink when printing on the machine.

5. Lightfastness testing of ink

The light resistance of the ink is a performance of the ink to keep the color stable after seeing the light. Poor light resistance of the ink after a time of light, fading phenomenon will occur. Some printed materials in the printing plant when the color meets the requirements, and after a period of use at the customer will produce the phenomenon of color deviation, the reason for most of this.

Here is a rough detection of ink light resistance method: the printing or plate after the field color sample into two parts, part of the exposure to daylight for about 4 hours, the other part placed in the shade to avoid light; or the color sample folded in half and placed in the daylight, part of the printing face up, so that daylight, part of the printing face down backlight placed. 4 hours after the color deviation against these two parts of the color sample, if There is an obvious color deviation, it means that the light resistance of this ink is not qualified.

Printers in the purchase of ink, ink suppliers should be required to provide accurate color phase, coloring power stable products, and to leave a certain amount of safety stock, do not occur in the case of broken material.

*Disclaimer: The content contained in this article comes from the Internet, WeChat public numbers and other public channels, and we maintain a neutral attitude toward the views expressed in the article. This article is for reference and exchange only. The copyright of the reproduced manuscript belongs to the original author and the institution, and if there is any infringementPlease contact Jetson Chemical for deletion