Multi-Emulsion in cosmetics

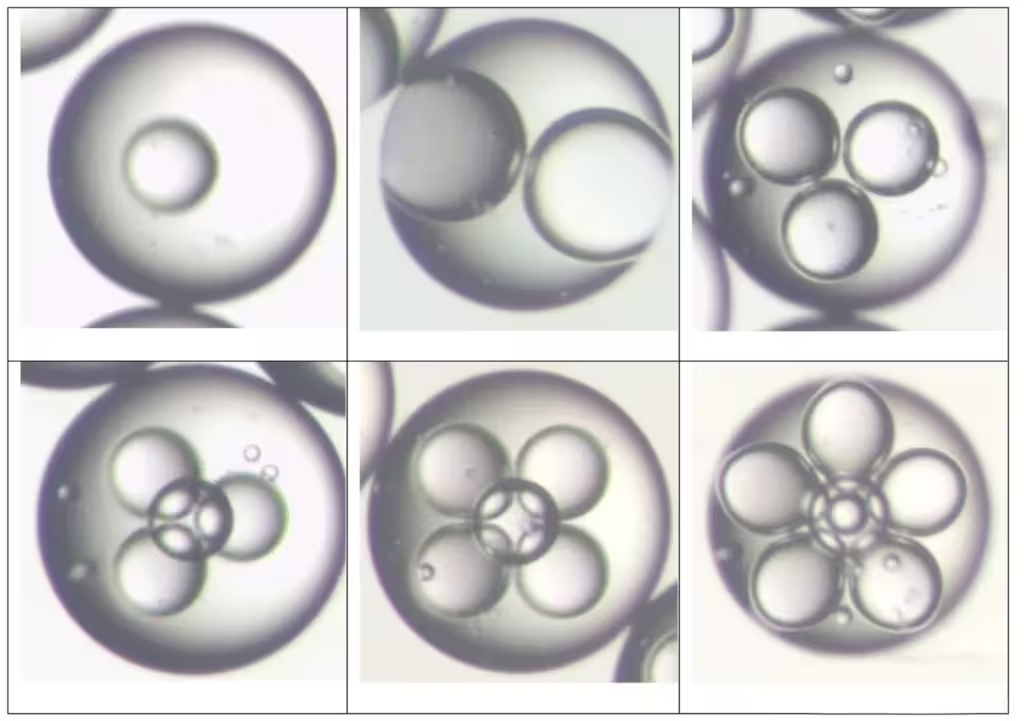

Multiple emulsions (W/O/W and O/W/O) are considered to be an ideal cosmetic system that can contain multiple active ingredients at the same time, is gentle on the skin, and is a dispersion system that is both functional and cosmetic.

The unique “three-phase, two-membrane” structure of multiple emulsions makes it possible to simultaneously encapsulate active ingredients of different nature and efficacy, while at the same time providing isolation, protection, slow-release, odor and color masking of the encapsulated ingredients, etc. However, due to the inherent complexity of multiple emulsions, they have not been widely used.

What is Multi-Lotion

Multiple emulsion, also known as composite emulsion, referred to as compound emulsion, is an emulsion dispersed in another continuous phase of the formation of multi-layer emulsion, are generally highly dispersed, particle size of the multi-phase system, there are a variety of types, to the water-in-oil-in-water (W/O/W), water-in-oil-in-water-in-water (O/W/O) the 2 most common types.

W/O/W type: W/O emulsion is dispersed in another continuous aqueous phase to form the system. Due to the special structure of multiple emulsions, after adding the active ingredient in the inner water phase, the active ingredient needs to pass through two interfaces to be released, which can delay the release of the active ingredient and prolong the action time of the active ingredient.

O/W/O type: A system in which an O/W emulsion is dispersed in another continuous oil phase. As a system in which both the outer and inner phases are oils and fats, the system can be divided into three immiscible regions (oil phase/water phase/oil phase) due to the presence of the O/W and W/O double interfacial films, thus realizing the coating and slow release of oil-soluble active ingredients.

Preparation of multiple emulsions

The main preparation methods for multiple emulsions are one-step emulsification, two-step emulsification, membrane emulsification, and microfluidic control preparation, etc. The two-step method is shared below:

W/O/W emulsion: The first step is to prepare a W/O emulsion with a lipophilic emulsifier, and then add the emulsion dropwise to an aqueous phase containing a hydrophilic emulsifier to produce a W/O/W multiple emulsion.

O/W/O emulsion: the inner oil phase, water phase and outer oil phase were heated respectively; the inner oil phase was added while stirring the water phase, and the initial emulsion was ultrasonicated to form an O/W emulsion; then, the O/W emulsion was added to the outer oil phase and mixed and cooled down to room temperature, and the O/W/O multi-structured emulsion was prepared.

Multiple breast influences

Emulsifier dosage

Emulsifier is an important factor to maintain the stability of emulsion, especially for multiple emulsions; some studies show that too low or too high W/O emulsifier content is not conducive to the formation of multiple structures in the system; the higher the content of O/W emulsifier, the easier it is to form stable multiple emulsions. The stability of multi-structured emulsions is directly related to the amount of emulsifier used, and the effects of the amount of internal and external phase emulsifiers on the structure and stability of multi-structured emulsions vary slightly depending on the system.

food additive

The introduction of electrolytes (e.g., sodium chloride, glucose, acetic acid, etc.) into the aqueous phase of multiple emulsions can regulate the osmotic pressure between the inner and outer aqueous phases to bring them into equilibrium. And the imbalance of osmotic pressure between the inner and outer aqueous phases will cause the contraction or dissolution of droplets, which is one of the main reasons for the instability of W/O/W emulsions.

Preparation process

During the preparation of multiple emulsions by the two-step emulsification method, the intensity of emulsification, homogenization time, and emulsification temperature at each stage affect the formation of multiple emulsions and their stability to a certain extent;

Different stirring speeds may affect the size and structure of the prepared particles there are differences in the size of the droplets is also an important factor affecting the stability of the multi-structured emulsion; temperature has a greater impact on the formation of multi-structures, mainly including the emulsification temperature during the preparation process as well as the storage temperature of the system at a later stage.

Application of multiple emulsions in cosmetics

Enhances the skin feel experience

Chemical sunscreens with high SPF are greasy and do not feel good in the summer. Water-in-oil systems do not feel good on the skin and have problems with sunscreen penetration, while oil-in-water systems are difficult to waterproof. The use of multiple emulsions in the development of sunscreens not only reduces the irritation of sunscreens on the skin, but also avoids the unpleasant skin feel of the traditional water-in-oil system.

Multiple protection and slow release of active ingredients

After the multiple emulsions encapsulate the actives, the actives in the inner phase need to pass through the two membranes to be released, so the multiple emulsions have a good protection and slow release effect on the actives.

*Disclaimer: The content contained in this article comes from the Internet, WeChat public numbers and other public channels, and we maintain a neutral attitude toward the views expressed in the article. This article is for reference and exchange only. The copyright of the reproduced manuscript belongs to the original author and the institution, and if there is any infringementPlease contact Jetson Chemical for deletion