The detergent effect of surfactants is the basic property of surfactants that has the greatest practical use. It is involved in the daily life of millions of households. It is also increasingly used in all walks of life and in various industrial production. Ltd. produces sodium rosinate, triethanolamine and other series of products that have been affirmed by the majority of users. Here the technical department of Dayao Chemical makes the following explanation on the anti-static effect of surfactants.

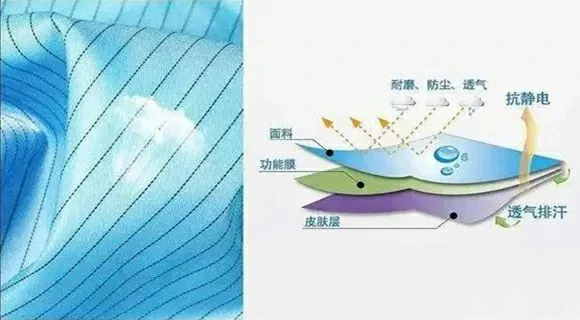

Fibers and plastics and other products are often due to friction generated by static electricity and affect the application performance of its products. Such as fiber fabrics with static electricity, often appear “sticky” or “static sticky”, as well as easy to absorb dust or become dirty and other shortcomings. Plastic products with electrostatic impact is even greater, not only products easy to adsorb dust. Affect the transparency of its products and surface cleanliness and beauty, but also reduces the performance and value of the products.

In order to eliminate this electrostatic phenomenon, the surfactant antistatic method is mostly used. This kind of surfactant is called antistatic agent.

The first section of the electrostatic phenomenon and the causes of

The order of fiber charging by different determiners obtained some differences in the results, but for wool, nylon and synthetic wool and other such fibers with amide bonds tend to have a positive charge.

Section II Antistatic agents

There are two main methods of eliminating static electricity.

1, physical method, because the size of static electricity by the temperature and humidity, so you can use to adjust the temperature and humidity, corona discharge and other physical methods to eliminate the phenomenon of static electricity on the surface of the goods.

2、Surface chemical method, that is, the use of surfactants also known as antistatic agents on the surface treatment of fibers and plastic products or mixed in the interior of the plastic to achieve the purpose of eliminating static electricity.

I. Antistatic agent for fiber

1. Types of antistatic agents: The main types of antistatic agents used in fibers are cationic and amphoteric surfactants.

2. Mechanism of action of antistatic agents: Surfactants used in fiber antistatic, antistatic mechanism: mainly in the prevention of frictional electrostatic and surface charge escape on the surface of the fiber fabric two aspects. The prevention of frictional charging is closely related to the structure of the surfactant, while the escape of surface charge is related to the amount of adsorption and moisture absorption of the surfactant on the fiber fabric.

Second, the antistatic agent of plastic

The mechanism of action of surfactant as an antistatic agent for plastics is that the surfactant is adsorbed on the surface of plastic with hydrophobic hydrocarbon chains through van der Waals forces and extends outward with polar groups, forming a directional adsorption film of surfactant on the surface of plastic with electrical conductivity so that the electrostatic charge can be well dissipated. At the same time, the adsorption film can also play a role in easing the friction of the plastic surface.

*Disclaimer: The content contained in this article comes from the Internet, WeChat public numbers and other public channels, and we maintain a neutral attitude toward the views expressed in the article. This article is for reference and exchange only. The copyright of the reproduced manuscript belongs to the original author and the institution, and if there is any infringementPlease contact Jetson Chemical for deletion