Typical features

- Colorless and odorless viscous liquid with hygroscopicity.

- Soluble in water and ethanol, with hydrophilic groups in the structure to improve water solubility.

- Stable performance.

- Plasticizing effect.

Product Use

- Used as a solvent for nitrocellulose, rubber, resin, grease, paint, pesticide, etc.

- Commonly used as textile auxiliaries, solvents, plasticizers for rubber and resins.

- An important monomer for the synthesis of photographic resins and cross-linking agents, also used in adhesives for polyester sheet bases.

- Excellent dewatering agent for associated gas and carbon dioxide in natural gas fields.

- Triglyceride plasticizers for polyvinyl acetate resins, polyvinyl chloride, fiberglass and asbestos pressboard.

- Air fungicides.

- Tobacco desiccant, fiber lubricant and desiccant for natural gas.

- For organic synthesis to produce brake fluids with high boiling points and good low temperature properties.

- Improvers of lubricant viscosity.

Quality Indicators

| Item | Indicator |

| Appearance | Colorless transparent viscous liquid |

| Purity wt % | ≥95 |

| Density (20°C) | 1.124-1.130 |

| Ash W % | 0.005 |

| ferrous ion ppmw | 1 |

| Moisture content % | ≤0.1 |

| color and luster Pt-Co | ≤25 |

| HLB value | 40 |

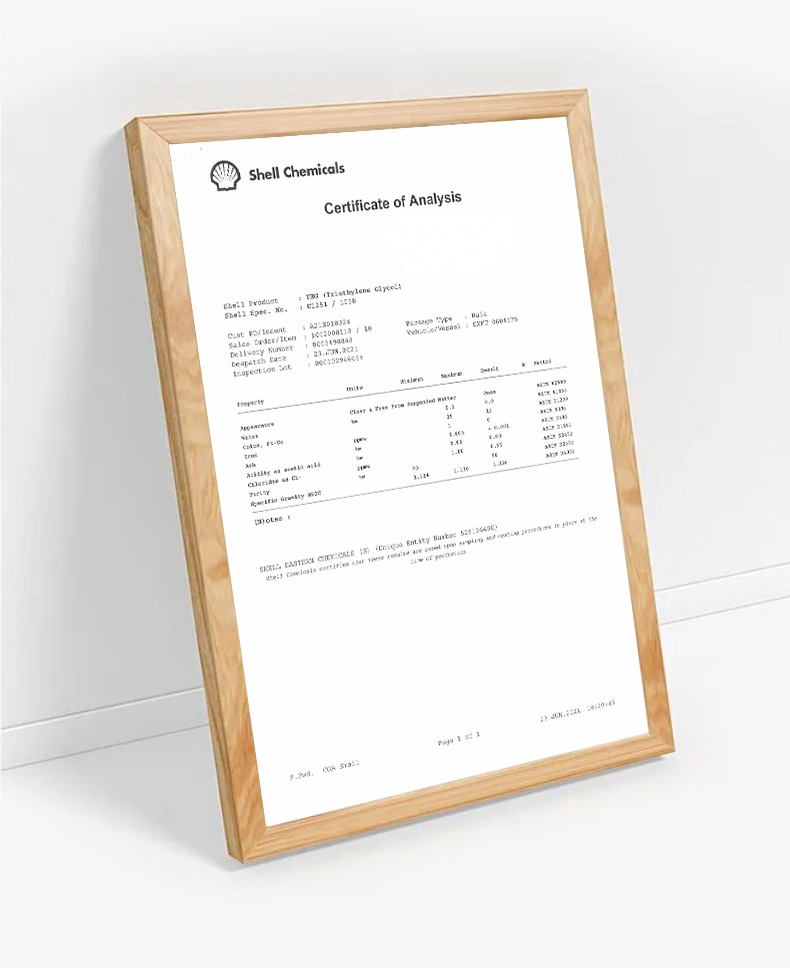

Testing Certificate

How to use

Note: The operator wears a self-absorbing filtered dust mask, chemical safety glasses, toxic-proof work clothes and rubber gloves.

A: Preparation of triethylene glycol diacetate plasticizers

| NO. | Items | % |

| 1 | Triethylene glycol | 54.95 |

| 2 | acetic acid | 45 |

| 3 | P-Toluenesulfonic acid | 0.05 |

| 4 | Acetic anhydride | 2-5 |

| 5 | Sodium carbonate water | 10-15 |

| 6 | Salt water | 30-50 |

| 7 | Activated carbon | 1-8 |

Take 54.95% of triethylene glycol, 45% of acetic acid, 0.05% of sulfuric acid or p-toluenesulfonic acid, put it in the sandwich reactor and heat esterification, the temperature is 90-130℃ under normal pressure, dehydrate continuously, add 2-5% of acetic anhydride, react again for 30 minutes, evaporate its water and acetic acid under reduced pressure, reduce the reaction solution to 30 -40℃, add 10-15% sodium carbonate aqueous solution to neutralize to pH7.0-7.5, then add 30-50% salt water, stir and leave to stratify, separate out the triethylene glycol diacetate layer, dehydrate under reduced pressure, add 1 – 8% activated carbon is added to decolorize the product, and then pressed and filtered to obtain triethylene glycol diacetate used as plasticizer for vinegar fiber filter nozzle.

B: Preparation of high-matching quality melt by alcoholysis of waste polyester textiles with triethylene glycol

C: Preparation of a triethylene glycol diisooctanoate

Package specification

- Specification:200g / 500g / 5kg / 20kg

- This product is not dangerous goods, and can be transported as general cargo.

Storage conditions

- Protected from exposure, rain and high temperature

- Products should be stored in airtight containers, avoid freezing and high temperature

- Whenever possible, it should be used within ten months

- The recommended normal storage temperature is 10-35℃